The article presents an in-depth analysis of various structural solutions for the working bodies of potato planting machines designed to apply mineral fertilizers simultaneously with planting operations. Based on the conducted research, an innovative design of a furrow opener was developed, which is equipped with a specialized spreader intended for subsurface placement of mineral fertilizers during the potato planting process. The distinctive feature of this spreader is its configuration—a freely rotating ring outfitted with oppositely oriented blades, which ensures uniform dispersion. Through theoretical modeling and calculations, the optimal geometric and operational parameters of this working unit were determined. The study substantiates that the implementation of the proposed design significantly enhances the uniformity of fertilizer distribution both in terms of lateral spread and depth within the potato ridge, thereby improving agronomic efficiency and contributing to better crop development.

| Published in | American Journal of Mechanics and Applications (Volume 12, Issue 3) |

| DOI | 10.11648/j.ajma.20251203.14 |

| Page(s) | 45-51 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Potato Planter, Furrow Opener, Spreader, Hiller, Frame, Fertilizer Tube, Fertilizer, Soil, Potato Ridge

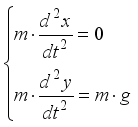

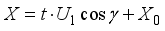

(1)

(1)  (2)

(2)  (4)

(4)  (5)

(5)  (6)

(6)  (7)

(7)  (8)

(8)  (9)

(9)  (10)

(10)  (11)

(11)  (12)

(12)  (13)

(13)  (14)

(14)  (15)

(15)  (16)

(16)  (17)

(17)  (18)

(18)  (19)

(19)

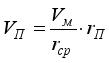

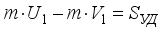

VП | Speed of the Bar |

Vм | Working Speed of the Machine |

rср | Average Radius of the Embedded Bar |

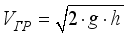

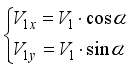

Vгр | Speed of Mineral Fertilizer Granules During Their Fall in the Fertilizer Tube |

h | Fall Height (Length of the Fertilizer Tube) |

g | Acceleration Due to Gravity |

| [1] | Pryanishnikov D. N. The importance of chemicalization, increasing our yields, and ensuring their stability. Proceedings of the Russian Academy of Sciences - Moscow - 450 p. |

| [2] | Sokolov A. V. Distribution of nutrients in the soil and crop yield - Moscow, Publishing House of the Russian Academy of Sciences, 1997 - 328 p. |

| [3] | Batyrov Z. L., Shakhabov S. Sh. Machines for applying fertilizers under the cotton sowing rows - Karshi: Nasaf, 2008 - 98 p. |

| [4] | Bogdevich I. M. Soil fertility and the role of the agrochemical service in its regulation. In the book: “Modern problems of increasing soil fertility in Belarus and ways to solve them.” Minsk, 1998. pp. 13-22. |

| [5] | N. M. Komilov, Sh. Abduganiyev. Sliding (rolling) movement of fertilizers along the guide in the fertilizer-applying working body of a combined machine for inter-row cultivation. Journal of Mechanics and Technology, Vol. 5, No. 1, 2024, Special Issue. |

| [6] | Postnikov A. N. Potatoes / Crop Production. Edited by G. S. Posypanov. - Moscow: Kolos, 1997. - pp. 267-301. |

| [7] | E. A. Ivanyuin, R. S. Khachukaev. Effectiveness of applied fertilizers for potatoes. "Bulletin of Kurgan State Agricultural Academy" No. 1, 2018, pp. 27-30. |

| [8] | Korshunov A. B. Yield and quality management of potatoes. - Moscow: VNIIKH, 2001 - 367 p. |

| [9] | Kvasnyuk N. Ya. Potato system [Electronic resource]. Access mode: |

| [10] | Gilmanova L. R., Bayboboev N. G., Abdualiev N. Kh. Justification of the design parameters of a compaction roller for creating longitudinal furrows in cotton inter-rows. In: Modern directions for increasing the efficiency of transport systems and engineering structures in the agro-industrial complex. - 2022. - pp. 47-52. |

| [11] | Bayboboev N. G., Asatillaev Yo. M., Khaydarov A. K. Technological properties of soil affecting the performance of agricultural machines. In: Contribution of university agricultural science to the innovative development of the agro-industrial complex. - 2019. - pp. 49-54. |

| [12] | Patent 276212, RU, Ridge-forming cultivator-fertilizer / Kostenko M. Yu., Teterin V. S., Lipatov N. V. [et al.] - Published 16.12.2021, Bulletin No. 35. |

| [13] | Patent 16051U1, RU, Development of a seeder-cultivator unit for soil-surface sowing / Zimmerman A. E., Pautov P. I. - Published 10.12.2000, Bulletin No. 20. |

| [14] | Utility Model Patent RU 213790 U1, Opener / Kostenko M. Yu., Teterin V. S., Bayboboev N. G. [et al.] - Published 29.09.2022, Bulletin No. 28. |

APA Style

Bayboboev, N., Vladimir, T., Nikolay, L., Nematilla, K., Gulomov, S. (2025). Calculation of the Working Body of a Potato Planting Machine for Applying Mineral Fertilizers Under the Soil. American Journal of Mechanics and Applications, 12(3), 45-51. https://doi.org/10.11648/j.ajma.20251203.14

ACS Style

Bayboboev, N.; Vladimir, T.; Nikolay, L.; Nematilla, K.; Gulomov, S. Calculation of the Working Body of a Potato Planting Machine for Applying Mineral Fertilizers Under the Soil. Am. J. Mech. Appl. 2025, 12(3), 45-51. doi: 10.11648/j.ajma.20251203.14

AMA Style

Bayboboev N, Vladimir T, Nikolay L, Nematilla K, Gulomov S. Calculation of the Working Body of a Potato Planting Machine for Applying Mineral Fertilizers Under the Soil. Am J Mech Appl. 2025;12(3):45-51. doi: 10.11648/j.ajma.20251203.14

@article{10.11648/j.ajma.20251203.14,

author = {Nabijon Bayboboev and Teterin Vladimir and Lipatov Nikolay and Komilov Nematilla and Shukurjon Gulomov},

title = {Calculation of the Working Body of a Potato Planting Machine for Applying Mineral Fertilizers Under the Soil},

journal = {American Journal of Mechanics and Applications},

volume = {12},

number = {3},

pages = {45-51},

doi = {10.11648/j.ajma.20251203.14},

url = {https://doi.org/10.11648/j.ajma.20251203.14},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.ajma.20251203.14},

abstract = {The article presents an in-depth analysis of various structural solutions for the working bodies of potato planting machines designed to apply mineral fertilizers simultaneously with planting operations. Based on the conducted research, an innovative design of a furrow opener was developed, which is equipped with a specialized spreader intended for subsurface placement of mineral fertilizers during the potato planting process. The distinctive feature of this spreader is its configuration—a freely rotating ring outfitted with oppositely oriented blades, which ensures uniform dispersion. Through theoretical modeling and calculations, the optimal geometric and operational parameters of this working unit were determined. The study substantiates that the implementation of the proposed design significantly enhances the uniformity of fertilizer distribution both in terms of lateral spread and depth within the potato ridge, thereby improving agronomic efficiency and contributing to better crop development.},

year = {2025}

}

TY - JOUR T1 - Calculation of the Working Body of a Potato Planting Machine for Applying Mineral Fertilizers Under the Soil AU - Nabijon Bayboboev AU - Teterin Vladimir AU - Lipatov Nikolay AU - Komilov Nematilla AU - Shukurjon Gulomov Y1 - 2025/07/30 PY - 2025 N1 - https://doi.org/10.11648/j.ajma.20251203.14 DO - 10.11648/j.ajma.20251203.14 T2 - American Journal of Mechanics and Applications JF - American Journal of Mechanics and Applications JO - American Journal of Mechanics and Applications SP - 45 EP - 51 PB - Science Publishing Group SN - 2376-6131 UR - https://doi.org/10.11648/j.ajma.20251203.14 AB - The article presents an in-depth analysis of various structural solutions for the working bodies of potato planting machines designed to apply mineral fertilizers simultaneously with planting operations. Based on the conducted research, an innovative design of a furrow opener was developed, which is equipped with a specialized spreader intended for subsurface placement of mineral fertilizers during the potato planting process. The distinctive feature of this spreader is its configuration—a freely rotating ring outfitted with oppositely oriented blades, which ensures uniform dispersion. Through theoretical modeling and calculations, the optimal geometric and operational parameters of this working unit were determined. The study substantiates that the implementation of the proposed design significantly enhances the uniformity of fertilizer distribution both in terms of lateral spread and depth within the potato ridge, thereby improving agronomic efficiency and contributing to better crop development. VL - 12 IS - 3 ER -